When it comes to t-shirt serigraph printing, we have an expanded palette. Yet, the most popular one is screen printing Today, we`ll focus on the best five serigraph printing approaches for personalized t-shirts.

There are several ways you can print, as far as the inks are concerned.

Now, we’ll be talking about this from a more professional way. When screen printing becomes all about quantity, it becomes much cheaper and easier, because the more t-shirts you produce, will balance the time required to prep the screens. We have discussed previously about this business.

There is a ton of different serigraphs methods and I’m going to go through the most popular ones. Screen printing is the way for you to go and figure out what makes the most sense:

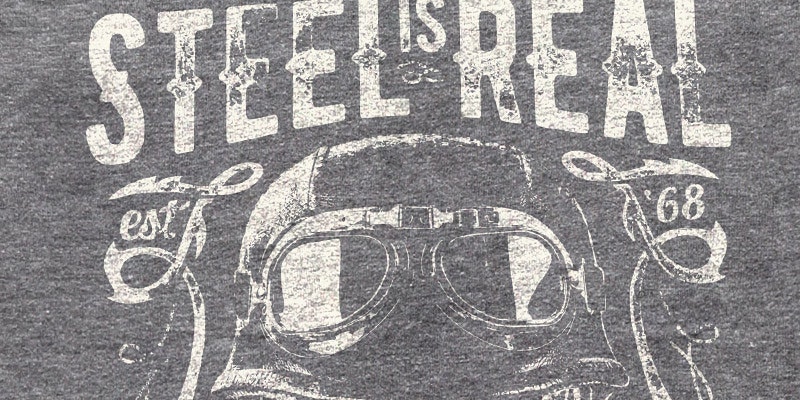

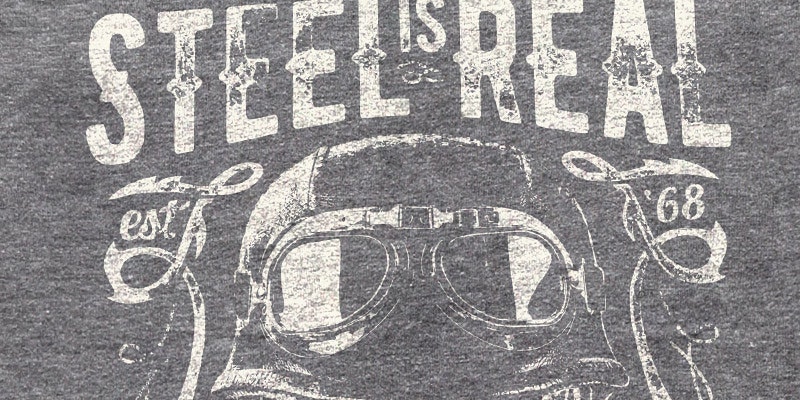

1.PLASTISOL- this is perhaps the most common and cheap ink used for t-shirt printing

Plastisol, it’s a very robust type of ink, that stands up over time.

Is oil-based, so cleaning it will require chemicals. If you’re environmentally friendly, you will tend to avoid.

Despite that aspect, it is definitely the most popular and it can be printed on both black or white colored shirts. Keep in mind that anything printed over a white base will pop and shine a little bit more. Also, consider that each color is adding extra cost. So the more colors you choose for a t shirt design, the more expensive gets.

You can do quite large colored printed designs if you want to. 8, 10, 12 colors, depending on how many stations the screen printer has and their automated or hand done presses.

Around three colors designs are the cheapest and affordable. As you go beyond that, things can get expensive.

So, you should be thoughtful about how many colors you’re using, because is having an impact on the final cost.

On white shirts, you don’t have to use that backer color because you’re printing on a nice light color. That’s definitely a positive. Another plus of printing on lighter colored t-shirts is that the less ink, the softer the shirt will feel.

So, one color over white it will feel slighter inky than let`s say, the Rolling Stones logo.

Another downside is that as it gets older they tend to crack. So if your favorite t-shirt that has a bunch of little crack marks over time, you can go for the next method:

2 WATER BASED PRINTING, as opposed to plastic, uses inks that are water-based

Unlike plastisol, this is a super soft print. Water-based printing is easy to clean up. You won’t need chemicals to clean off the inks.

Water-based printing is pretty much the environmentally choice because it’s all clean. You wash down the drain and you’re good to go. It works best on lighter garments because it doesn’t have the incredible coverage like plastisol inks.

Used on darker fabrics, water-based printing will give you a bit of vintage or faded feel. If you have questions on what will look better on your shirt, it’s always worth asking the printers. Remember that they see this stuff every day.

3. DISCHARGE SERIGRAPH- the bleaching method

If you bleach out the black of a t-shirt, this becomes much more vibrant and it pops easier. It is also much softer. This happens because bleaching it out as opposed to putting a thick cover of ink over it. Instead of normal ink, discharge inks are used. This removes the shirt`s dye. It is related to bleaching in design, except it doesn`t damage the fibers. It will change the color to be whatever color you choose to.

Keep in mind that the way those t-shirts react to the process of discharge printing can be different. Most printers have preferred textures and even preferred colors to work on when using this particular method.

A definite benefit to discharge printing is that after the first wash the t-shirt becomes very soft. You can barely feel the print at all.

Discharge printing is a bit more of a difficult process than water-based or plastisol printing. We deeply recommend a high-quality printer.

4. CMYK PRINTING.– Cyan yellow magenta and black to emulate a photorealistic print

It sure won’t be as crisp as a real photo, but they can do a pretty darn good job.

CMYK printing or four-color process printing. May seem a bit difficult to get vibrant and accurate colors. You’re dealing with just four colors! Yes, you can use four colors and get incredible color detail and amazing color depth.

Always be mindful if you’re trying this stuff. Simulated process printing like this, is a quite technical thing for the printer to do. Find a talented printer to do this, especially the color separation process.

First, run it through a piece of software that will sort of break up the colors. Then, manually adjust the darkness of all those films. There’s usually a bit of testing involved.

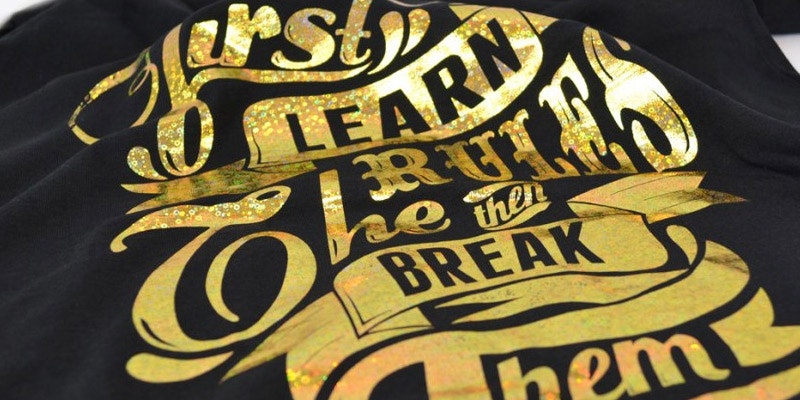

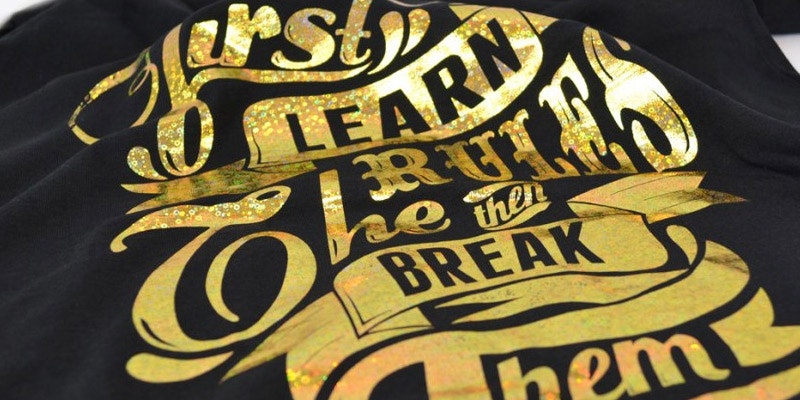

4 With serigraph, you can FOIL print as well

The t-shirt is covered with an adhesive. Then the foil comes over that adhesive. Once it is laid down, the excess is removed. Where there was adhesive on the shirt, the foil will stay.

Where the adhesive was not, the foil will be gone. Smooth, right?

Usually, foil printed t-shirts don’t last that long through washes.

An alternative is metallic inks. It won’t be as shiny, but they’ll hold up much longer. Also, they’re cheaper to do. So, if you want to pull off gold colors there are multiple ways to do it.

5 DYE SUBLIMATION SERIGRAPH – all-over t-shirt print

A lot of print on demand printers will use this method. Dye sublimation is your design printed out onto a giant piece of paper. This will be big enough to cover the entire t-shirt. For this, we use a special type of paper called sublimation paper. First, the design is printed out on that giant sheet of sublimation paper. After that, is turned over, so that the ink touches the t-shirt.

Then, a heat press compresses that ink onto the t-shirt, which causes it to stick. When the paper is removed, TA DAM, your colorful design will appear on the t-shirt. If you want a 100% cotton t-shirt, the sublimation is not an option. Because you`ll need a high polyester count on your tee.

Anyway, this is a cool method of printing because is full-color. You can use as many colors as you want and it won’t impact price. However, dye sublimation is the most expensive way of printing t-shirts. There are many steps involved and it uses a lot of ink. The price is the opposite of plastisol ink.

As a closure, I prefer screen printing, because I like the process and colors hold up really well. Also, it covers up all the professional ways of printing. From basic to the high-end products. On the other hand, direct-to-garment printing has come a long way in a short period of time. About this, in a future article. Stay tuned!