News trend

Apparel printing techniques

In the apparel industry, besides the artwork to be printed, the most important thing is the printing techniques we`re using. There are several printing techniques, and each of them is suitable for a certain business strategy. I hope this will answer many questions concerning the perfect printing technique for your t-shirt business. This is quite simple to see which one fits your needs best, because each printing technique has its pros and cons depending on the number of colors used, on the timing, and not the least, on the costs. I am going to explain each of them and let you decide which method you would prefer.

Apparel printing techniques

SCREEN PRINTING

It’s the most commonly used method for t-shirt printing. It uses screens pressed up against cloth to place paint onto shirts one color per screen. Each press uses a single color, so that means that for a t-shirt design that has 5 colors, you will need 5 separate screens. Screen printing is high quality, professional looking, durable, and can be very price effective on volume orders. Some cons might be the fact that it’s messy to work with many screens. If you want to do one t-shirt or two, that’s definitely not the right choice for printing. Also, screen printing has setup fees, depending on the number of the color screens to be burned. For example, Customink uses this kind of printing when it comes to bulk orders.

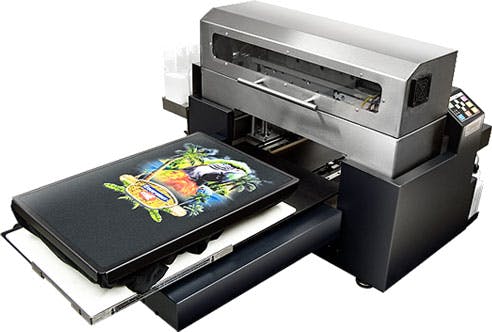

DIRECT TO GARMENT PRINTING (DTG)

While screen printing technique is considered to be traditional and known by everybody, direct to garment printing is fairly new. Because it is new, the printer is also very expensive, but the quality of the printed t-shirts is excellent. With the direct to garment printers, the design is printed directly on a t-shirt or on the desired product. The art process allows unlimited colors and shades to be printed, thing that could not be possible with the screen printing. It is the perfect option for photo t-shirts and very detailed images. Direct to garment printing is considered to be the only professional option for low run orders. That means you can print one t-shirt or 100 without problems. The printing process in the case of DTG takes longer than in the case of screen printing and the big disadvantage is that the artwork can’t be printed on dark t-shirts (with few exceptions). Also, that’s the reason why the printer does not print the white color. The result is professional and designs are not felt on the garment.

HEAT PRESS TRANSFER PRINTING

is probably the best choice for a small business, and we are not talking here about starting a clothing line. The heat press transfer technique consists of printing a transparent ink with the use of a computer on a special piece of paper ( Inkjet transfer paper). Full color images and of very high quality can be printed, then applied to the cotton garment and pressed in the heat press. The usual temperature is 180 degrees for 10 – 30 seconds. With the heat transfer, you can print complex designs, with many colors. The advantage is that the colors don’t require to be applied separately. The heat press transfer is ideal for creating fast customized t-shirts. The bad thing is that the colored picture can be applied only on light t-shirts, because the colors in the design might be affected by the t-shirt color. Even that it’s fast and easy to print a t-shirt with the heat press transfer, the feel on transfer is heavy, and it cracks easily.

HEAT TRANSFER VINYL PRINTING

is the perfect option for t-shirt lettering, for small t-shirt orders, for name of bands, clubs, football player and so on. It requires a machine (vinyl cutter) to cut out designs on special color sheets of vinyl. The cut vinyl is applied onto the garment using a heat press.

Heat transfer vinyl is not headed towards mass production, because of the heavy feel of the transfer and also because many colors printing is hard to achieve and need separately heat transfer. There are 50 colors to chose from, including fluorescent colors. This technique is perfect of you want a t-shirt with distinct lettering.

DYE SUBLIMATION PRINTING

is actually the heat transfer onto polyester garments and polyester coated items (such as mugs). Dye subprocess is limited to printing on white or light to medium colored garments that have a 100% polyester surface and allows for full-color printing as well as spot color printing on garments. Sublimation ink is a special ink that turns to gas when the heat is applied. The heat makes polyester pores to open and permanently absorb the sublimation ink. But this is possible with most of the non-textile garments, like mugs, puzzles, key chains, mouse pads etc. This technique can also be applied to polyester t-shirts, but there is a restrained demand in this chapter. Dye sublimation printing also requires a special transfer paper which is cheaper than inkjet transfer paper, but the sublimation ink is very expensive.

Besides these techniques, there are plenty more. Here are some of them, even that they are not used as often as the above ones, they are required in some business areas: plastisol printing, waterbased printing, non-PVC printing, discharge printing, metallic inks, glitter inks, foil, gel, 3d printing, cut and sew, embroidery, thermochromic, photochromic (color changing).